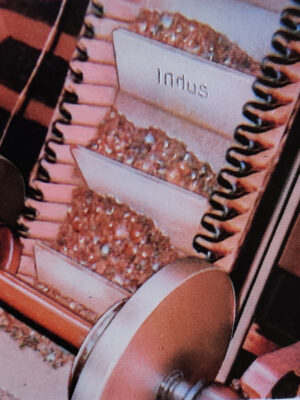

Description

Superior Impact Resistance

When compared to conventional multiply conveyor belts with a similar tensile strength, Indus Super Impact stands out with its superior impact resistance. The maximum impact energy of a single ply Indus Super Impact type 630/1 is comparable to that of a 4-ply EP belt type 630/4.

Superior Rip Resistance

Indus Super Impact has a rip resistance that is more than four times greater than conventional multiply conveyor belts that have a similar tensile strength. The rip resistance is not only superior in relation to the multiply EP Conveyor Belts, but also when compared to Solid Woven.

Lower Belt Weight

When compared with the conveyor belts having the same grade of the tensile strength, the Straight Warp belt provides 5% to 20% lesser weight leading to power saving. Indus Super Impact is an extremely cost-effective solution. A lighter belt type can be used in many applications due to its excellent operational characteristics and finger splice efficiency. The combination of these factors has been proven to result in exceptionally low operating costs per ton.

Lower Belt Thickness

The carcass thickness of both Indus Super Impact 1 Ply & 2 Ply is similar or smaller than those of comparable multiply EP conveyor belts. For example, the Indus Super Impact 630/1 carcass has a thickness of 3.2 mm, compared to 5.0 mm for the EP 630/4. As a result, the required drum diameter may be smaller in some cases.

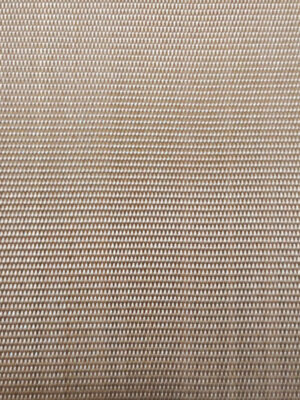

Superior Tear Resistance

The tear resistance of Indus Super Impact also leaves conventional multiply conveyor belts with a comparable tensile strength far behind. The tear resistance is measured according to the international ISO 505 standard.

Lower Belt Thickness

The carcass thickness of both Indus Super Impact 1 Ply & 2 Ply is similar or smaller than those of comparable multiply EP conveyor belts. For example, the Indus Super Impact 630/1 carcass has a thickness of 3.2 mm, compared to 5.0 mm for the EP 630/4. As a result, the required drum diameter may be smaller in some cases.