Description

Areas of Usage

Steel Industry, Cement Industry, Coal & Coking Industry, Construction Industry, Potash and Salt Mining, Stones and Earth, Fertilizer & Chemical Industry, Recycling Plant , Agriculture, etc.

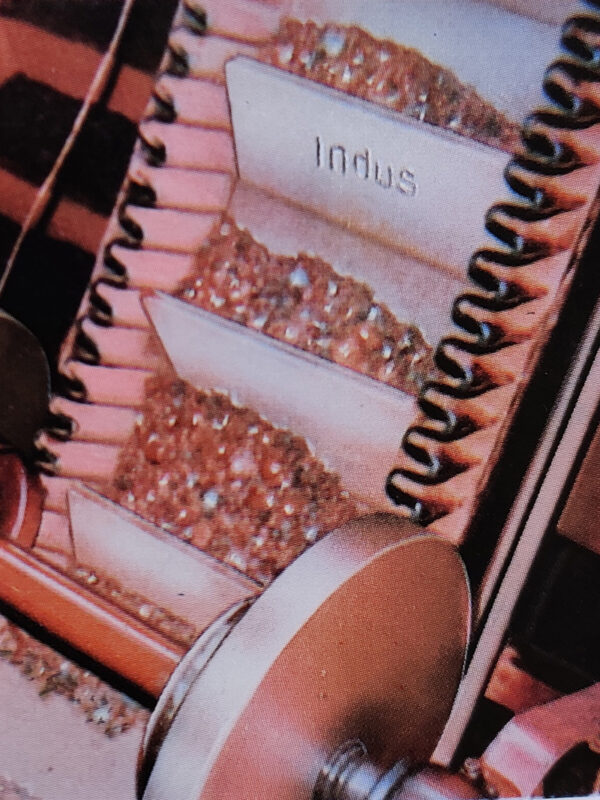

INDUS SUPER TREKKER Steep Angle Conveyor Belt is made up of below listed components:

Indus Cleats

Indus cleats are designed with proper rigidity to preclude excess backward bending due to gravitational force exerted by the material loaded in the cleats. By seeing certain critical applications, we have modified all type of cleats with Synthetic fabric reinforcement to avoid tearing due to material gravitational force. Depending upon the angle of inclination & the other factors the type of cleat is selected from the below listed range of Indus Cleats:

Type ‘T’, ‘K’, ‘TKS’ & ‘TKS3P’ cleats are reinforced into the side walls using metal fasteners

The sizes not mentioned in this table can be manufactured up on request.(SIZES IN MM)

| SR. NO | TYPE | HEIGHT | BASE WIDTH |

|---|---|---|---|

| 1 | ‘T’ | 75 | 75 |

| 2 | ‘T’ | 110 | 100 |

| 3 | ‘K’ | 75 | 100 |

| 4 | ‘K’ | 100 | 100 |

| 5 | ‘TKS’ | 75 | 75 |

| 6 | ‘TKS’ | 110 | 100 |

| 7 | ‘TKS’ | 140 | 150 |

| SR. NO | TYPE | HEIGHT | BASE WIDTH |

|---|---|---|---|

| 8 | ‘TKS’ | 180 | 150 |

| 9 | ‘TKS’ | 220 | 150 |

| 10 | ‘TKS’ | 240 | 150 |

| 11 | ‘TKS’ | 280 | 190 |

| 12 | ‘TKS3P’ | 280 | 230 |

| 13 | ‘TKS3P’ | 330 | 230 |

| 14 | ‘TKS3P’ | 380 | 230 |

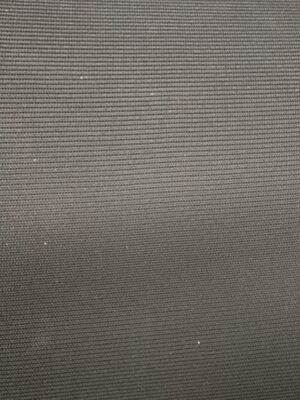

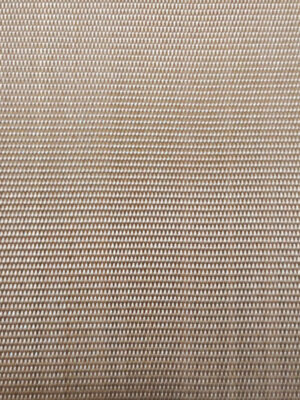

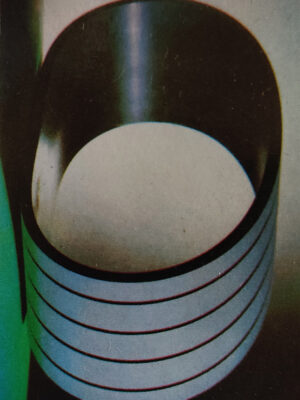

Indus Side Wall

The side wall has been designed to achieve adequate rigidity to avoid the buckling under compression experienced by it at the point of deflection. The top portion of the side wall has been designed against tear & gauging resistant by using special rubber compound having high elongation at break. The side walls are fully reinforced with synthetic fabric to get better life.

The sizes not mentioned in this table can be manufactured up on request.(SIZES IN MM)

| SR. NO | TYPE | HEIGHT | BASE WIDTH | PITCH |

|---|---|---|---|---|

| 1 | SW | 40 | 60 | 40 |

| 2 | SW | 60 | 60 | 40 |

| 3 | SWF | 60 | 60 | 40 |

| 4 | SWF | 80 | 60 | 40 |

| 5 | SWF | 100 | 60 | 40 |

| 6 | SWF | 100 | 80 | 60 |

| 7 | SWF | 120 | 80 | 60 |

| 8 | SWF | 160 | 80 | 60 |

| 9 | SWF | 200 | 80 | 60 |

| 10 | SWF | 240 | 80 | 60 |

| 11 | SWF | 260 | 80 | 60 |

| 12 | SWF | 300 | 80 | 60 |

| 13 | SWF | 350 | 100 | 60 |

| 14 | SWF | 400 | 100 | 60 |

Indus Fasteners

All belts are given further reinforcements by mechanically fixing the sidewall to each cleat with fasteners, washers and moulded nylon sidewall supporting fixture. The same can be applied with or without the side blinkers.

Indus Slide Blinkers

Available as an option, side blinkers are placed between the wall and cleat. is installation will minimize the amount of material catching in between the corrugations and the cleat, therefore reducing carry back and spillage. Particularly useful in applications where the material is small and free flowing.